We care for our animals by protecting them along all stages of our supply chain.

Find out moreLink copiato negli appunti

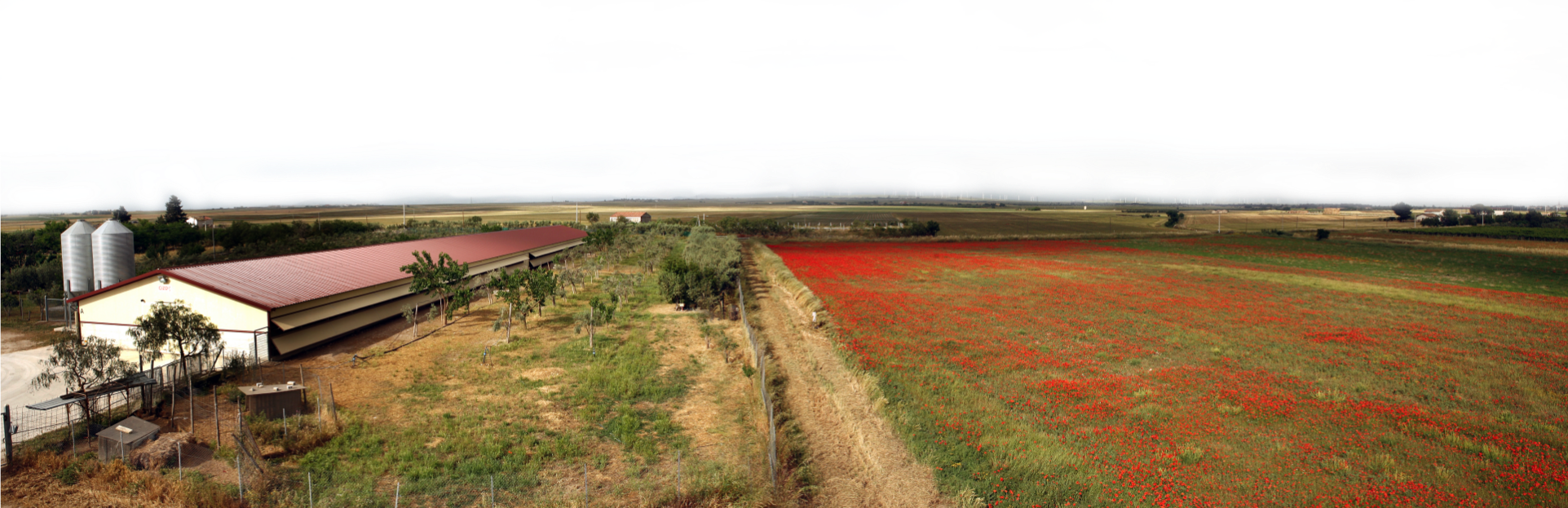

Integrated Supply Chain

The Amadori Integrated Supply Chain enables us to control all phases of the production process, including the acquisition of raw materials, feed production, the management and growth of the animals, food transformation, and the marketing and distribution of the product.

Controlled supply chain certifications:

DTP CSQA 035

DTP CSQA 126

The integrated supply chain is our company's strength. It allows us to ensure compliance with high control and quality standards so we can offer you various versatile and tasty products.

Campese is a 100% Italian slow-growth chicken, raised outdoors without antibiotics and fed an exclusively vegetable and GM-free diet.

100% Italian chickens and turkeys, raised without antibiotics and fed with exclusively vegetable and GM-free feed.

100% Italian chicken, raised outdoors without the antibiotics and fed with organically farmed cereals and legumes.

We care for our animals by protecting them along all stages of our supply chain.

Find out more

We have tried for years to use antibiotics more responsibly, and we can say that we have achieved important results.

Find out more